-

SMT

-

Through-hole

-

Mixed technologies

Built for Customization.

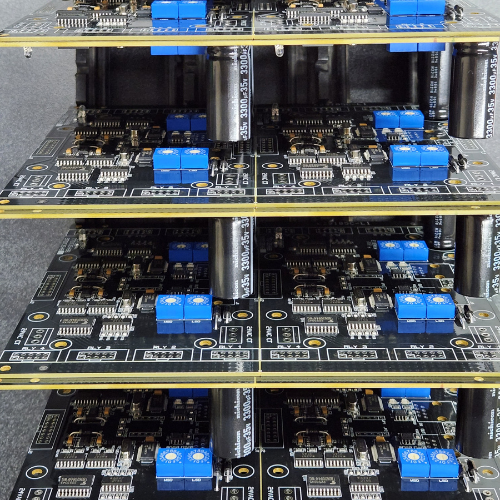

Since 1996, Auscon has been trusted by OEMs in Southern Minnesota and the surrounding regions as a leading local provider for surface-mount technology (SMT), thru-hole and mixed technology assembly.

Agriculture • Transportation • Industrial Equipment • Appliances • lighting • Data & Communications • Sporting Goods

INDUSTRIES SERVED

• Agriculture

• Transportation

• Industrial Equipment

• Appliances

• lighting

• Data & Communications

• Sporting Goods

Our Services

Auscon provides the efficiency of automated equipment along with the flexibility of manual assembly.

This enables us to meet your custom PCB assembly needs with precision and within your budget. We pride ourselves on offering fair pricing and excellent customer service.

Check out our 1-minute video to see Auscon's capabilities in action!

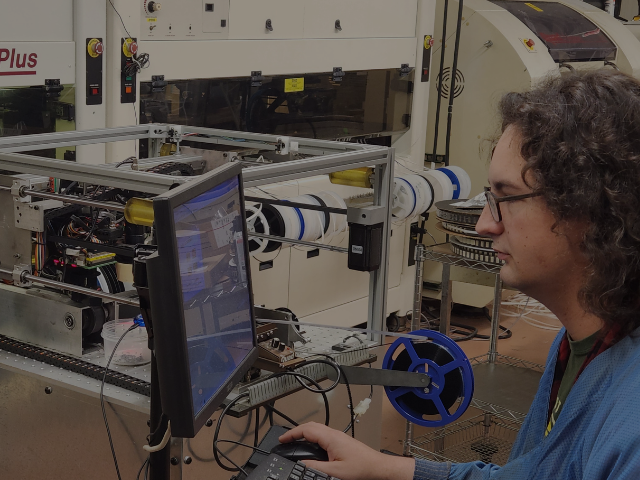

Powered by Automation

Our facility is equipped with three fully-automated SMT lines, enabling us to execute ongoing production and new project set-ups simultaneously. These highly-versatile pick-and-place systems operate at the speed of a turret machine while still maintaining the precision needed for fine pitch placement. This gives us the ability to place all chip sizes without slowing the line down, making our automated services the ideal solution for your custom OEM application.

To read more, click on the arrow to the right of each listing:

-

IC Programming

Auscon has the unique capability to pre-program microcontroller units (MCUs) “on the fly” as part of the SMT line, eliminating the need to stock pre-programmed chips or parts.

-

Selective Solder

We provide precision soldering services for thru-hole, mixed-technology boards and complex designs. Nitrogen generation connected, our process reduces oxidation and strengthens the solder joint, reducing the risk of electronic failures.

-

Automated Optical Inspection (AOI)

Our advanced imaging technology provides exceptional defect coverage, including automatic solder joint verification and identification of surface, dimensional or component placement faults.

-

Conformal Coating

Auscon offers both complete board or select component, conformal coating. Our application process provides coating that is consistent, accurately controlled and cost-efficient. While silicone is the most common material requested, we also work with other materials such as acrylic or polyurethane to fit your technical need.

-

Aqueous Batch Cleaning System

To ensure our water is non-conductive and to reduce spotting and residue, Auscon uses a five-step treatment process: softening, dechlorination, reverse osmosis and two stages of deionization. This process is especially important to prevent high-impedance circuits from operating out of spec.

Flexible with manual assembly

Auscon's highly-skilled manual technicians have the specialized experience and knowledge to meet unique assembly needs, including:

- Quick-turn First Article builds

- Unusual board designs

- Custom parts or sub assemblies

- Non-standard component placement

- Manual inspections

- Ultra delicate components

While our automated machinery is already equipped to handle complex designs, when you have an application that requires even greater ingenuity, flexibility or customization, our manual assembly team can help.

.png)

.png)

.png)

.png)

.png)

.png)

our capabilities

Auscon offers partial turnkey, full turnkey and kitted / consigned assembly services. We also have a strong network of reliable, local suppliers to help you source alternative parts in case of supply chain issues, design updates or other procurement support needs.

- Automated machinery: sizes up to 15" x 18"

- Manual assembly: formats up to 20" x 20"

-

Single

-

Double-sided

-

Multi-layer

- Wide variety of materials

Solder Assembly & Finishing

- Selective (down to 3mm)

- Reflow

- RoHS / lead-free

- Leaded

- No-clean or water wash process

Component Placement

- Centering from 0201 packages through QFP208 and BGA

- Fine pitch down to 0.3mm

Electrical Testing

- Basic continuity

- Functional

- Advanced (e.g. burn-in services) with client-provided equipment

our capabilities

Auscon offers partial turnkey, full turnkey and kitted / consigned assembly services. We also have a strong network of reliable, local suppliers to help you source alternative parts in case of supply chain issues, design updates or other procurement support needs.

-

SMT

-

Through-hole

-

Mixed technologies

- Automated machinery: sizes up to 15" x 18"

- Manual assembly: formats up to 20" x 20"

-

Single

-

Double-sided

-

Multi-layer

- Wide variety of materials

Solder Assembly & Finishing

- Selective (down to 3mm)

- Reflow

- RoHS / lead-free

- Leaded

- No-clean or water wash process

Component Placement

- Centering from 0201 packages through QFP208 and BGA

- Fine pitch down to 0.3mm

.png?width=100&height=100&name=Untitled%20design%20(8).png)

Electrical Testing

- Basic continuity

- Functional

- Advanced (e.g. burn-in services) with client-provided equipment

.png?width=200&height=200&name=Auscon_IC%20Programmer_500x500%20(1).png)

IC Programming

In addition to offering this advanced service as an integrated option for PCB assembly projects, Auscon also offers IC programming as a stand-alone service. We support a wide variety of package types and create affordable tooling for almost any chip, including BGA, QFP, QFN, TSOP, PLCC and SOIC. Both matrix tray and tape-and-reel services are available.

Design Engineering

Whether your in-market application is experiencing field failures, we're conducting a manufacturability review or you need a prototype, you're in good hands with our engineering team. With over 30 years of experience in PCB assembly, Auscon has the specialized knowledge you need to prevent and correct potential issues in your application.

From Assembly Floor to Your Doorstep.

.png?width=512&height=512&name=noun-delivery-5438690-FFFFFF%20(2).png)

Auscon offers options for hand-delivery of your PCB assembly order, direct from our facility to yours. We can often help you save on shipping costs compared to freight services. Contact us to find out if your delivery location is eligible.

.png)